Your Hub for GMP Automation & Industrial Networking Knowledge

Explore our latest articles, videos, and podcasts on GMP compliance, industrial networking, data integrity and more tailored to help biotech manufacturers modernize and stay compliant.

Scroll to Explore

GMP Automation, Industrial Networking, and Other Lucid Automation Articles

Lucid Automation is proud to attend this year’s ISPE Facility of the Future conference in San Diego.

We will have a booth staffed with our expert team that turns GMP manufacturing challenges into scalable solutions driving quality and productivity. Lucid Automation provides production-critical automation and process data solutions that help biotech and pharmaceutical manufacturers stay efficient, compliant, and innovative. Based in the San Francisco Bay Area, we specialize in GMP automation, industrial networking, and analytics for regulated life science facilities. [more…]

Who would have guessed that taking a handful of commercial-off-the-shelf, proprietary bioreactors for cellular agriculture and unifying them under a single automation platform for data analytics would be such a major step toward a hybrid “dim factory”?

The high-level, non-confidential case study is now live on Automation World.

Without changing code or re-architecting the network, we deployed our rugged FAT infrastructure kit preconfigured with Rockwell Automation FT View, Software Toolbox Top server (withdrivers), FT Historian SE, and AVEVA PI Vision.. [more…]

Life is too short for poor batch implementations. Many organizations are purchasing equipment—especially bioreactors—with an inappropriate batch philosophy, resulting in systems that can produce but are frustratingly inefficient and cumbersome to operate.

This isn’t about dressed-up sequencers masquerading as batch systems; it’s about major vendors supplying batch systems intended for a Process Development (PD) environment into commercial settings. [more…]

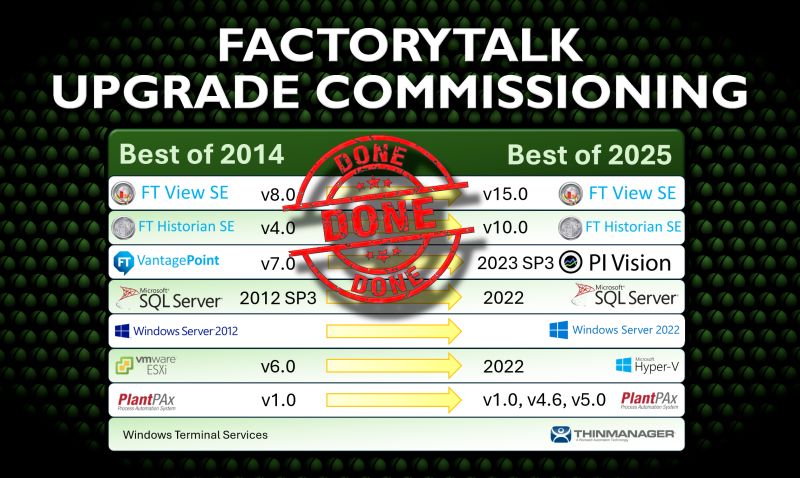

Finally got the go-ahead to upgrade a system I installed back in 2014, and the results are sweet. Zero downtime, more speed, less resources for the plant thanks to some clever application of tools that avoided a full re-validation.

This virtual infrastructure was Phase 1 to clear the way for new equipment and retrofitting existing equipment with modern PLCs. The whole site is shooting for upgrades to be completed in 2026. [more…]

Wildtype Foods, a leader in cultivated seafood, engaged Lucid Automation to validate whether real‑time data capture and remote visualization could push their new San Francisco pilot plant closer toward an autonomous, lights‑out manufacturing model.

This historian pilot proves that cultivated meat facilities can achieve immediate gains in visibility, compliance, long-term market viability, and labor efficiency without a plant-wide retrofit. By combining Lucid’s automation expertise with Wildtype’s vision for sustainable protein, the team has taken a concrete step from theory to practice on the lights-out journey.

In a two‑week sprint Lucid delivered a mobile, rugged, self-contained server that bolted onto Wildtype’s network to pull bioreactor data into a FactoryTalk Historian SE / PI Vision stack. These components generated electronic batch reports (EBRs), dashboards, and trends for engineers monitoring production runs. [more…]

Automation gains are often realized on the back end of a project. Having a strategy upfront increases the effectiveness, cost, and maintenance of your equipment. Automation seems to get attention only when things go poorly, so let us highlight some non-obvious gains you have likely experienced but didn’t notice because it “just worked”.

The non-obvious gain from reducing duplicated effort is costs, effort, and [more…]